Packing pallets to improve stability avoids the frustration of your customers receiving damaged goods as they make their way through the supply chain. Avoid product damage with these seven packing tips will go a long way toward insuring the products arrive in tact.

- Make sure you start out with good quality wooden pallets, none that are damaged or broken.

- Choose the correct sized pallet to fit the boxes you’re shipping. The boxes should be arranged so that they come as close to the edge of the pallet as possible with no overhang. Overhang can cause damage and may wind up costing you more because certain carriers may charge more if your pallet exceeds their standards. And bringing the boxes as close to the edge of the pallet as possible will make it easier to apply strapping.If your product does not stack to conform to any of the standard sized pallets, Greenway Products & Services will design a custom pallet size that can save your transportation costs, as well as better protect your product.

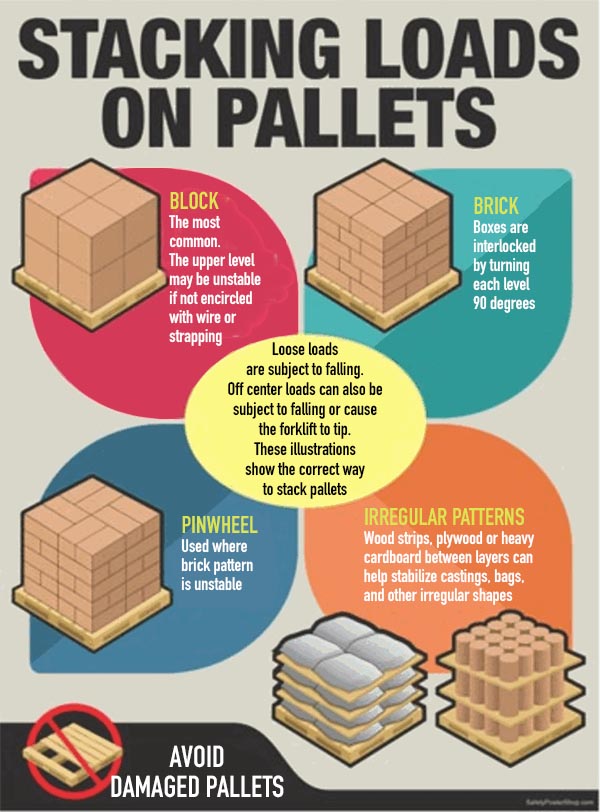

- Use a “brick laying” or “pinwheel” pattern when packing your pallets. This helps create more stable columns of boxes. It also helps avoid tipping and sliding during transportation.

- When you build your pallet make sure the heaviest good go on first to help create a stable base. Another advantage of heaviest on the bottom is that you will avoid crusher lighter goods.

- Avoid creating a shipping “pyramid”. It’s best not to pack smaller boxes toward the top of the stack. Try to get the smaller boxes to fit into the more stable cube pattern. A stack that gets narrower at the top becomes less stable and can lead to product damage.

- Strapping the freight to the pallet is the next important step to keeping your shipment secure. It’s best to use heavy-duty packing bands made from a strong product such as steel or polyester. It’s recommended that at least two straps be used on each side of the pallet.

- Secure shrink wrapping is another key to keeling your product safe during shipping. It’s best to wrap pallets at least three times around the bottom two inches. Shrink wrap keeps the stacked boxes in place.

Of course you’ll be shipping products of different sizes, resulting in different sized boxes being loaded onto your pallets. If you create a design for different packing options you may be able to reduce the amount of packing materials required for each shipment and increase the stability of each pallet being shipped.

Following these tips will help avoid product damage and ensure that your product gets to its destination without damage, and that results in happy customers.

Greenway Products & Services, LLC will help you start out with high quality, sturdy pallets for your shipping needs. Greenway is a leading pallet recycler and re-manufacturer in the Mideastern region. We are a full-service pallet management company. “We have been able to achieve the industry’s highest on time delivery rate of 98.9% with the investments we have made in our manufacturing facilities,” says Dominick Davi, Greenway’s President of Products & Services.

Our goal at Greenway is to keep our customers’ business moving. Contact us for a quote today. Visit our website, www.greenwaypsllc.com or call us at 732-442-0200. We can deliver trailers to you on a moment’s notice throughout the Mideastern Region.

I found it helpful when you said that in order to keep your product safe during shipping, you must consider shrink wrapping. This made me remember warehouse owners that aim to have their goods delivered in the safest possible way. I could imagine how they could use do not stack pallet stickers for their shipments that should not be stacked.