Pallet Types

Skid

A skid has no bottom decking. Top deck boards rest on top of the perpendicular stringers. Typically it is only a 2-way pallet.

Pallet Parts

Width

Width

Direction of the deck boards.

Deck Boards

Deck Boards

Multiple boards placed perpendicular to stringer forming both the top and bottom of the pallet and sometimes the top only.

Span

Span

Distance between deck board supports, either stringers or block.

Overall Height

Overall Height

Vertical span between the floor and top side of the top deck.

Length

Length

Measurement of the stringer direction.

Leads

Leads

Boards at either end of the deck. Usually when leads are referred to they are wider than the inner boards for increasing structurally integrity. They will usually be 5.5 “wide and known as 6” lead boards.

Inners

Inners

Boards in between lead boards. Spacing requirements will usually dictate the number of inner boards used. On average, the width of an inner board is usually 3.5”.

Spacing

Spacing

The spacing between the deck boards. Space is most critical part of the top decking It’s usually dictated by the need to increase total weight across the entire surface or to accommodate the size or shape of the load so that product cannot tip or fall into the spacing. Lighter weight product with large foot prints can sometimes use fewer boards, thus saving money.

Flush

Flush

A pallet with deck boards flush to the stringer or block. No overhang.

Plug

Plug

The repair board attached to a defective stringer to make it usable again. A plug is can run the full length of a stringer or only over a section of the stringer being repaired. The number of stringers repaired is used as part of the grading process in GMA pallets.

Wing

Wing

The top only (single wing) or both top and bottom boards (double wing) overhang the outer stringers. Usually used for heavier weights such as cement block.

Wooden Stringer Pallet

Wooden Stringer Pallet Wooden Block Pallet

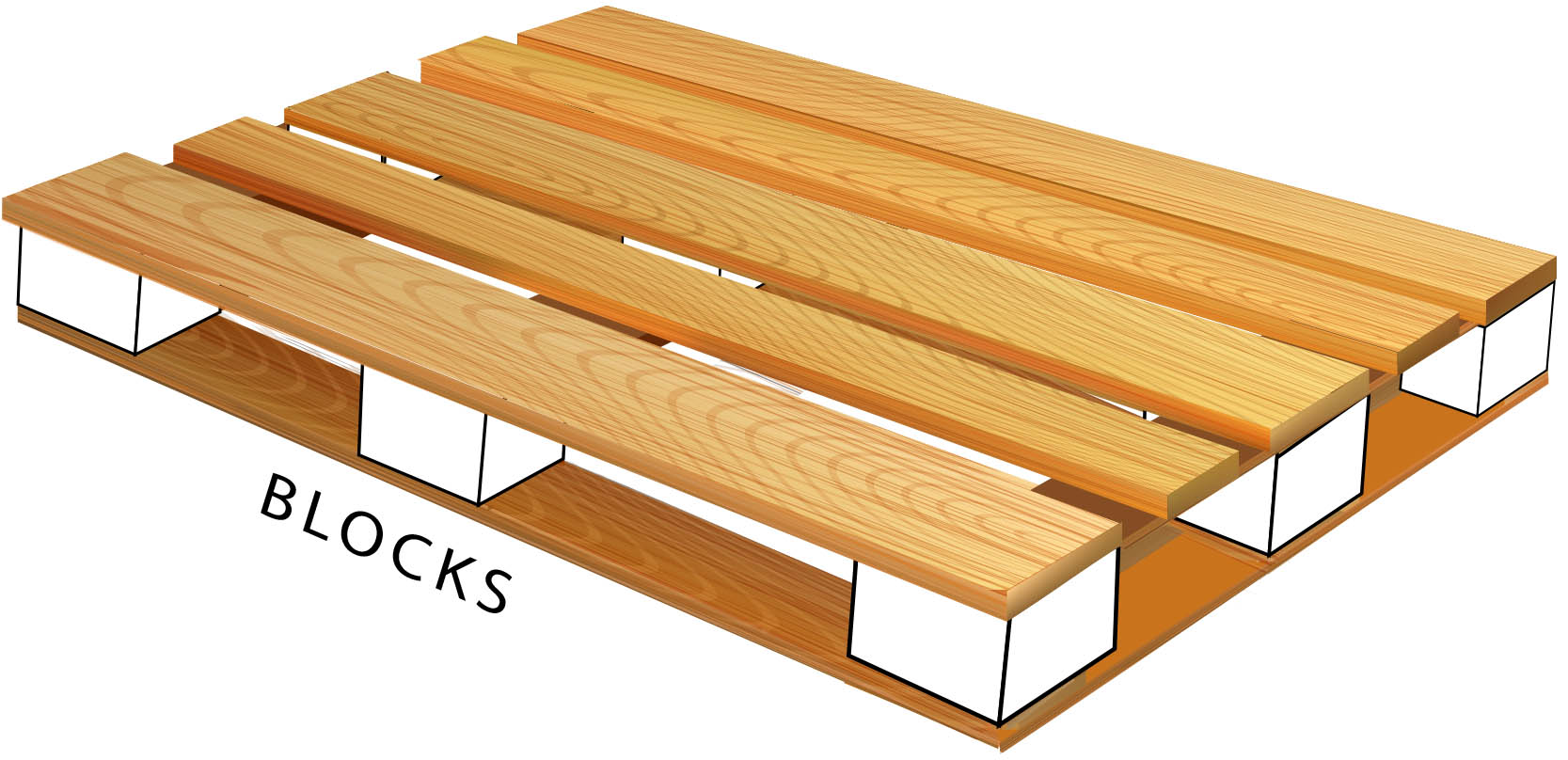

Wooden Block Pallet

Direction of the deck boards.

Direction of the deck boards.

Distance between deck board supports, either stringers or block.

Distance between deck board supports, either stringers or block.

A pallet with deck boards flush to the stringer or block. No overhang.

A pallet with deck boards flush to the stringer or block. No overhang.