Wooden pallets are one of the essential underpinnings of supply chains for all manner of products, nationwide and in the global market. In the United States alone, the US Forest Service estimates that there are currently more than 2 billion pallets currently in circulation. Given that the most commonly used pallet size measures 48 by 40 inches, it’s reasonable to ask where all the wood for these pallets comes from, and perhaps more critically, where does it all go?

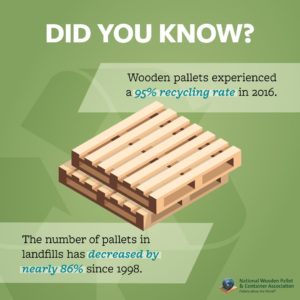

Wood is a robust and durable material for pallet construction, but the journey from manufacturing facility to warehouse to trucks to retailers is not a gentle one, and many pallets become damaged. The image of used and broken pallets piled in the back lot behind stores and businesses is a prominent one in the popular imagination, and the easy assumption is that these pallets are fated to end up in landfills. Fortunately, however, this is rarely the case any longer, as pallet recovery, reuse, and recycling has become more widespread.

Naturally, as the demand for pallets and similar packaging materials persists (and, in the face of the COVID-19 crisis, has only increased), so too does the pressure to make the most out of the pallets that already exist. According to statistical data from the US Forest Service, the year 2011 saw the manufacture of 416 million new pallets, while 474 million used pallets were recovered for reuse or recycling. The number of recovered pallets has grown significantly over the past 20 years; 1992 saw only 51 million pallets recovered. While some pallets do still find their way to landfills, about one-fourth of those discarded pallets are recovered for recycling on site. In addition, in the age of Pinterest a small but increasing number of used pallets are being claimed by crafters and DIY-ers for household projects and art.

When pallets are recovered, they are evaluated and sorted based on the amount of damage they have sustained during use. A little more than two-thirds of recovered pallets are repaired to be used again, while another 11.9 percent are in sufficiently good condition to be reused without repairs. Of those pallets that are more heavily damaged, 16.2 percent are dismantled and the boards that remain sound become replacement lumber or are used to construct new pallets made either from entirely recycled lumber or a mixture of recycled and new wood. Most of the remaining recovered pallets, 3.1 percent, are chipped or ground for use in various other applications. 55 percent of these ground or chipped pallets become landscaping mulch (44 percent colored, 11 percent uncolored), and another 10 percent becomes animal bedding. 30 percent of the chipped pallets become wood fuel pellets, boiler fuel, or similar energy sources, while the remaining six percent finds miscellaneous other purposes.

The push to improve pallet recovery efforts by the pallet recycling industry makes sense both from a business perspective and for ecological considerations. If 8 out of every 10 pallets used in the US can be reused with (or in some cases, without) repairs, it means that those pallets don’t need to be replaced with new ones, which saves on materials costs for the pallet manufacturer and reduces the industry’s consumption of new lumber, while at the same time keeping the majority of used pallets out of landfills. This is especially important given that the pallet and packaging industry uses one-third of the nation’s production volume of low-grade hardwood (the wood that is deemed too cosmetically flawed for use in furniture production). In the absence of regulations at the federal level mandating the recycling of wooden pallets and other fiber-based packaging, the pallet industry has still taken important steps to minimize the amount of wood material it contributes to the waste stream.

The push to improve pallet recovery efforts by the pallet recycling industry makes sense both from a business perspective and for ecological considerations. If 8 out of every 10 pallets used in the US can be reused with (or in some cases, without) repairs, it means that those pallets don’t need to be replaced with new ones, which saves on materials costs for the pallet manufacturer and reduces the industry’s consumption of new lumber, while at the same time keeping the majority of used pallets out of landfills. This is especially important given that the pallet and packaging industry uses one-third of the nation’s production volume of low-grade hardwood (the wood that is deemed too cosmetically flawed for use in furniture production). In the absence of regulations at the federal level mandating the recycling of wooden pallets and other fiber-based packaging, the pallet industry has still taken important steps to minimize the amount of wood material it contributes to the waste stream.

Because so many recovered pallets are reused or converted to lumber to repair other pallets, it is easiest to recycle pallets of the most commonly used sizes. In the US, the most popular pallet size is the 48 x 40 inch pallet typically used to transport grocery goods. There are two general designs used to construct pallets: stringer pallets, which have traditionally been more common throughout North America and are simpler to construct requiring fewer materials; and block pallets, which are more popular in Europe and have the advantage of being equally accessible by forklifts from all four sides, while stringer pallets are only fully accessible from two sides. Some large retail corporations, including Costco and Wal-Mart, have expressed clear preferences for block pallets due to their convenient four-way forklift accessibility, increasing pressure on suppliers to utilize these instead of stringer pallets. However, the two designs are made using different types of wood, which could pose supply challenges to stringer pallet manufacturers and complicate the issue of using repaired pallets and recovered pallet wood.

Greenway Products & Services, LLC is the largest pallet remanufacturer and recyclers in the New York metropolitan area. We also accept scrap wood and landscaping debris from our customers that we turn into valuable resources. Greenway is a full-service pallet management company. Contact us for a quote today. Visit our website, greenwaypsllc.com or call us at 732-442-0200. We can deliver trailers to you on a moment’s notice throughout the TNY-NJ-PA-MD-DE area.

Leave A Comment