It is widely known that when certain types of goods travel across international borders, there are procedures and regulations in place to ensure that no pests or pathogens that may be contaminating such goods are able to cross into new regions. This is why, for instance, regulations governing the transportation of live animals and foodstuffs are so strict. A pest or pathogen that is a controlled nuisance in its region of origin can quickly become a disastrous problem if introduced to a new ecosystem. Species that have evolved in the presence of a pest generally have some defenses or resistances that protect it, but the flora and fauna of other regions that have never been exposed to the pest may be highly vulnerable to it.

However, it is not only internationally-shipped goods that can serve as a transmission vector for invasive species, but the packaging materials in which those goods are shipped. To help prevent the introduction of invasive pests and pathogens to new regions, the International Plant Protection Convention (IPPC), part of the United Nations’ Food and Agriculture Organization, developed a safety standard for treating wood packaging used to transport goods. This standard, the International Standard for Phytosanitary Measures #15, or ISPM 15, requires that wood packaging be made of solid wood components which have been treated, either through heat treating or chemical fumigation with methyl bromide, according to approved methods to reduce the potential for contamination by pests and pathogens with the potential to be destructive to forests. Wood packaging that has been so treated is labeled with a special IPPC trademark to certify that it meets safety standards. Customs officials at international border crossings can look for these markings to determine whether shipments of goods may safely enter their country.

Ensuring compliance with ISPM 15 requires first understanding what kinds of packaging are required to meet this standard. Types of packaging that fall under ISPM 15 regulations include wooden packing cases, boxes, crates, pallets, dunnage, spools, reels, and cable drums. Types of packaging that are NOT required to adhere to ISPM 15 standards include:

- Packaging entirely made of processed wood material created using any combination of glue, heat, and pressure, including plywood, particle board, oriented strand board, and veneer

- Packaging made entirely from wood 6mm in width or thinner

- Barrels for wine and spirits that have been heated as part of the manufacturing process

- Wood shavings, wood wool, or sawdust

- Gift boxes made for cigars, wine, or similar commodities that have been treated as part of their manufacture

- Wood components that are permanently attached to freight vehicles or shipping containers

Certification requires the regulated types of wood packaging be sterilized against pests and pathogens either by heat treating or methyl bromide fumigation. Heat treating can be performed in a few different ways, including a standard heat chamber, a kiln, or a specialized microwave chamber. Regardless of the method, the temperature at the core of the lumber must reach 56° Celsius (133° F) and remain at that temperature for at least 30 minutes. It is critical for the temperature reading be taken from the core of the wood, as that is where destructive parasites and pests generally reside.

Methyl bromide fumigation requires that the wood be placed in a sealed container or tent, which is then completely flooded with methyl bromide gas, and remains there for at least 24 hours. While effective against invasive pests, this type of treatment is gradually being phased out due to concerns about the gas having the potential to contaminate the goods shipped using the treated packaging, especially food products.

Since the introduction of ISPM 15 regulations in 2003, more than 70 countries worldwide have adopted the requirements, with that list continuing to grow each year. Even if the destination country for a shipment does not require ISPM 15 compliance, it is considered good practice to use ISPM 15 certified wood packaging regardless, to avoid any potential issues at international border crossings. Some countries have additional regulatory standards, including the requirement that all lumber used in the construction of wood packaging be bark-free, which has a specific definition under ISPM 15 regulation, and requires that any bark remaining in the wane sections of the lumber used in the construction of wood packaging be removed prior to shipment. If you are uncertain of the requirements imposed by a destination country, contact the plant health authority of that nation.

When shipments are discovered to contain wood packaging that is not ISPM compliant, the response depends on the destination country, as each government has its own policies. Some countries will deny the shipment outright and require its return to the shipment’s point of origin. Others may fumigate the entire package, including its contents, and charge the shipper a premium rate for the trouble. Some countries replace the non-compliant packaging, charging a premium rate for the replacement, and send back the replaced materials. In some cases, non-compliant shipments have been incinerated or dumped in a landfill.

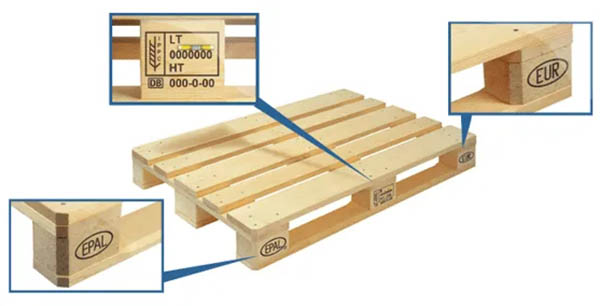

Common queries about ISPM 15 compliance include situations wherein shipping companies wish to build their own wood packaging from properly treated lumber, or have ISPM 15 marked wood packaging that they wish to reuse, repair, or modify. The first case is a difficult one; because the ISPM 15 marking is a certification for finished wood packaging materials, there is no way to simply buy “ISPM 15 certified lumber” and manufacture the packaging yourself. To guarantee the integrity of the certification mark, the IPPC only licenses the use of the mark to registered wood packaging production facilities. This allows the finished piece to be stamped, stenciled, or branded with the IPPC certification mark (generally on at least two opposing sides of the packaging). In theory, one could construct a new pallet or crate out of individual pieces of lumber that each have the IPPC mark, but this is generally not feasible from the perspective of either the packaging manufacturer or the customs official inspecting the package.

Countries Requiring ISPM 15

Algeria

Argentina

Australia

Bolivia

Brazil

Bulgaria

Canada

Chile

China

Colombia

Costa Rica

Cuba

Dominican Republic

Ecuador

Egypt

European Union

Austria

Belgium

Bulgaria

Croatia

Cyprus

Czech Republic

Denmark

Estonia

Finland

France

Germany

Greece

Hungary

Ireland

Italy

Latvia

Lithuania

Luxembourg

Malta

Netherlands

Poland

Portugal

Romania

Slovakia

Slovenia

Spain

Sweden

United Kingdom

Guatemala

Honduras

India

Indonesia

Israel

Jamaica

Japan

Jordan

Kenya

Lebanon

Malaysia

Mexico

New Zealand

Nicaragua

Nigeria

Norway

Oman

Paraguay

Peru

Philippines

Saudi Arabia

Serbia

Seychelles

South Africa

South Korea

Sri Lanka

Switzerland

Syria

Thailand

Taiwan

Ethiopia

Trinidad & Tobago

Turkey

United States

Ukraine

Venezuela

Vietnam

The issue of reuse, repair, and modification is a simpler one. Anyone may reuse ISPM 15 certified wood packaging as long as it is in usable condition and no components have been added or removed; the packaging retains its certification. However, if any portion of the packaging needs to be repaired through the addition and/or removal of materials, the packaging will need to be re-treated and re-marked by a certified kiln or fumigation facility. Likewise, an IPPC certified manufacturer may build onto an existing unit of certified wood packaging, as long as the original piece is unaltered and the additions are built from properly treated wood; the manufacturer would apply their IPPC mark to the newly built structure. However, only manufacturers who have ISPM 15 program certification may make any repair or addition to wood packaging bearing the IPPC label, as these modifications require re-marking the item.

ISPM 15 compliance is not only a regulatory necessity, it’s a responsibility for all companies that rely on wood and lumber to manufacture their shipping materials. The cost of eradicating invasive pests and the instability of the lumber supply these destructive species can cause is a major risk to the entire wood packaging industry, one we all must guard against.

Greenway Products & Services, LLC is the largest pallet remanufacturer and recyclers in NY, NJ, PA, MD, and DE. We also accept scrap wood from our customers that we turn into valuable resources. Greenway is a highly rated, full-service pallet management company. Contact us for a quote today at sales@greenwaypsllc.com. Visit our website, greenwaypsllc.com or call us at 732-442-0200. We can deliver trailers to you on a moment’s notice throughout the NY-NJ-PA-MD-DE area.

Leave A Comment