Every industry has its own patterns and trends that tend to repeat cyclically year after year. Understanding these patterns for your own business is one of the keys to success, but when you need shipping pallets to move your products from manufacture to warehouse to customers, it also helps to understand the cycles that dictate the prices of those pallets. When you recognize the forces that drive pallet prices and how they shift over the course of the year, you can plan ahead to buy the pallets your company needs at the time when pallet prices will be most favorable to you.

Data Source: https://fred.stlouisfed.org/series/WPU08410101

In response to supply chain issues caused by a number of factors, including the global pandemic and new tariffs, lumber prices began to surge in the latter half of 2020 and hit an unprecedented high in the second quarter of 2021. Since then, lumber prices have begun to return to more historically normal levels, but many industries that rely on lumber have yet to fully experience the effect of this equalization. Even then, the market for lumber remains somewhat volatile, given the high demand from the home construction industry and the unusually violent summer wildfires in the western US and Canada.

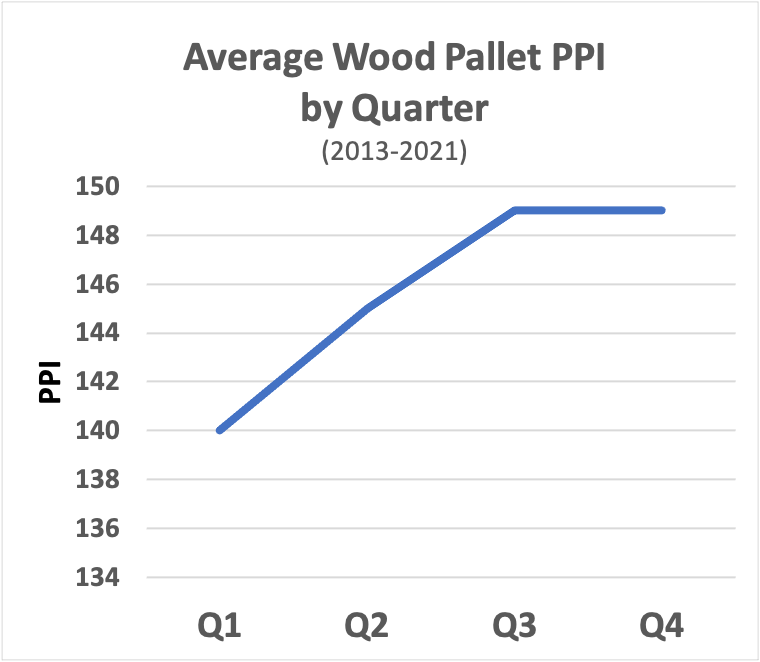

The overall pricing trends of the lumber industry do have an impact on pallet prices, but there are some more reliable patterns that can be identified within the shipping pallet and container industry specifically. These trends are generally centered around pallet supply and demand, which are determined by the need for pallets across a wide array of industries – particularly given that a handful of standard pallet sizes are commonly used across several different industries.

The demand for pallets generally increases when the industries that rely on them experience their heaviest shipping volumes, and across numerous industries, from grocery to electronics to toys and several others, the most busy shipping season is during the fourth fiscal quarter, in preparation for the holiday season in the final months of the year. Companies of all stripes need to move the most product during Q4, and as a result, need more shipping pallets than at any other time of year. This increased demand means supply is scarce for new buyers, and prices are commensurately high.

The best strategy to get the best deal on the pallets your business needs, assuming you have the flexibility to wait for better prices, is to buy your pallets when demand is lower, generally in the first half of the year in the spring and summer. By keeping an eye on lumber prices in conjunction with this cycle of demand for pallets, you may be able to zero in on the best moment to close the deal on the pallets your business needs. Even without a laser focus on lumber price trends, it’s a safe bet that setting up your pallet management program early in the year, during Q1 or Q2, will allow you to secure a better price than waiting until closer to the holiday season.

Even so, unforeseen circumstances do happen, and sometimes you need pallets when you need them, not when it would be most convenient to buy them. If you find your company needing to buy pallets during Q4, working with a pallet supply company that offers recycled and refurbished pallets can enable you to get the pallets your business needs at a more reasonable price. Refurbished and recycled wood pallets are also more ecologically sustainable, as the lumber used to construct them is reclaimed to make more pallets as long as it is structurally sound, after which it is repurposed into mulch or bio-fuel rather than ending up in a landfill.

While a number of factors impact the cost of wood shipping pallets, the simple answer to the question of when you should buy pallets for your business is this: New year, new pallet management program. You can make the review and upgrading of your pallet supply plan a part of your company’s spring cleaning process. That’s when pallets are likely to be most affordable, when demand quiets back down to normal levels in the aftermath of the winter holiday season.

About Greenway Products & Services

Greenway Products & Services is a pallet manufacturer and re-manufacturer as well as a full-service pallet management company servicing Maryland, Delaware, New Jersey, New York, and Eastern Pennsylvania. Greenway’s product line includes new, reconditioned/recycled, remanufactured, wood and plastic pallets in standard and custom sizes for domestic and international shipping. Greenway is one of the mid-Atlantic suppliers of heat-treated pallets. The company offers comprehensive pallet services, including pallet delivery, storage, removal and disposal, repair programs, ISPM 15 services, consulting services, excess pallet purchase program, drop trailer services, and trucking services. Greenway is part of the Kamps, Inc. family of companies.

Leave A Comment