Much of the Canadian trucker protest news coverage, and the blockage of trade that passes over the Ambassador Bridge connecting Windsor, Ontario to Detroit, focuses on its impact and interference with auto production lines. Little mention is made of consequence of timber imports – on the lumber used to build pallets, and its deleterious impact on every manufacturer that uses pallets to ship products.

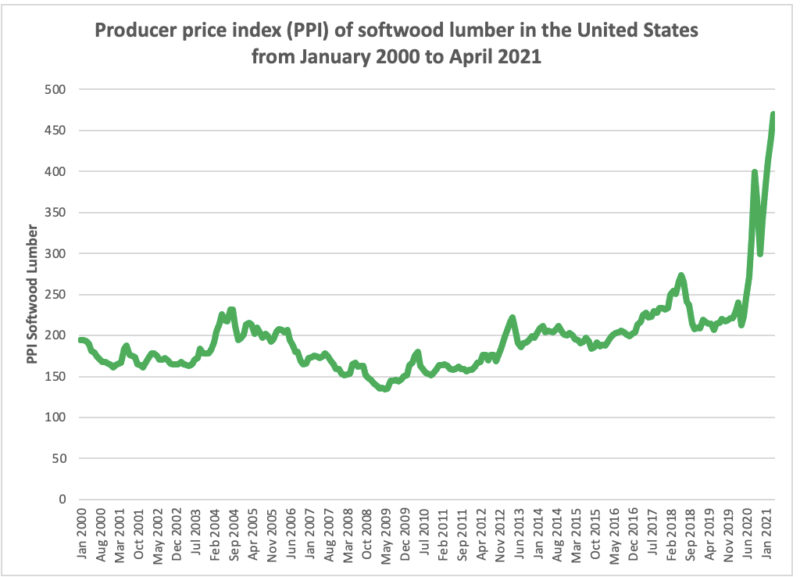

U.S. Producer price index (PPI) of softwood lumber Source: https://www.statista.com/statistics/195406/us-producer-price-index-of-softwood-lumber/

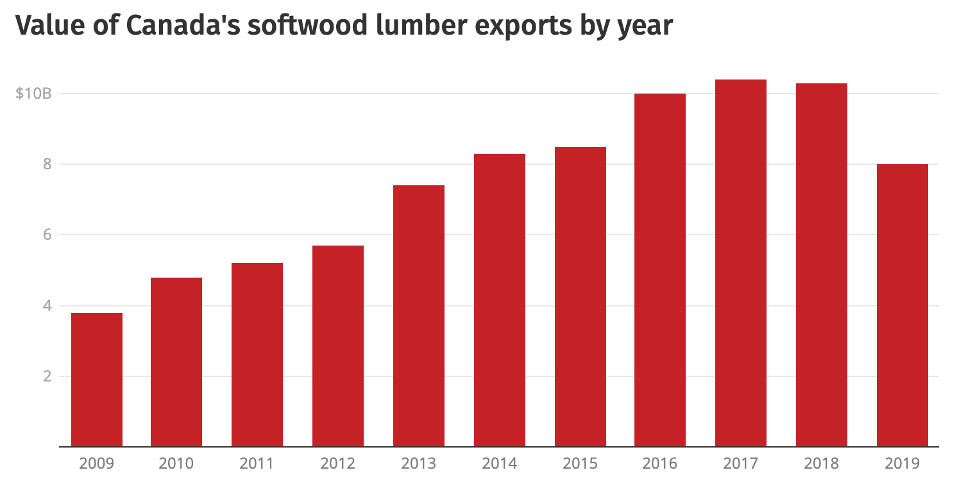

Canada is the source of most of the soft lumber used to build pallets in the United States, since we do not produce enough softwood to meet our own demand. The U.S. produces only 70% of the softwood lumber that is needed domestically. Most of the remaining softwood is imported from Canada, where 83% of total softwood lumber imported by value accounts for $4.5 billion in trade.1

Pallet producers rely on Canadian imports for pine lumber, specifically southern yellow pine (SYP), for several reasons. Southern yellow pine softwood:

- Is more consistent in weight than hardwoods

- Has a high strength to weight ratio

- Is easier to dry

- Helps prevent contamination from fungi, molds, or other pests

Stopping the flow of lumber imports from Canada impacts materials handling and logistics departments of every company that manufacturers, wholesalers, and distributes the products that get to our supermarkets and are delivered to our companies and homes.

Piling On

The Canadian Truck Blockade piles on costs to shipping departments on top of the additional lumber costs resulting from Canadian softwood lumber duty hikes, which have doubled and are now at 17.9%. Analysts such as Hamir Patel at CIBC calculate tariffs are responsible for an extra $99 in tariff costs alone for every thousand feet of softwood lumber imported from Canada. The extra importing costs have driven down the amount of lumber imported into the U.S., creating lumber shortages, and running up the cost of lumber even more.

All of us who are in the materials handling and logistics business are alarmed by the double hit to lumber costs.

Protect Against Volatile Price Hikes

The best way a company can protect itself from a shortage of pallets on hand, resulting in expensive production line interruptions, and from volatile price escalations is to establish on long-term contract with your pallet supplier. By estimating your pallet needs, work with your pallet manufacturer to produce and reserve the pallets at the delivery rate that best suits your usage patterns.

Call Greenway Products & Services to arrange for a pallet management program to protect your flow of pallets, as you need them, as well as provide the best protection you can to ward off the impact of the Canadian Truck blockades and Canadian tariffs.

About Greenway Products & Services

Greenway Products & Services is a pallet manufacturer and re-manufacturer as well as a full-service pallet management company servicing Maryland, Delaware, New Jersey, New York, and Eastern Pennsylvania. Greenway’s product line includes new, reconditioned/recycled, remanufactured, wood and plastic pallets in standard and custom sizes for domestic and international shipping. Greenway is one of the mid-Atlantic suppliers of heat-treated pallets. The company offers comprehensive pallet services, including pallet delivery, storage, removal and disposal, repair programs, ISPM 15 services, consulting services, excess pallet purchase program, drop trailer services, and trucking services. Greenway is part of the Kamps, Inc. family of companies.

Leave A Comment