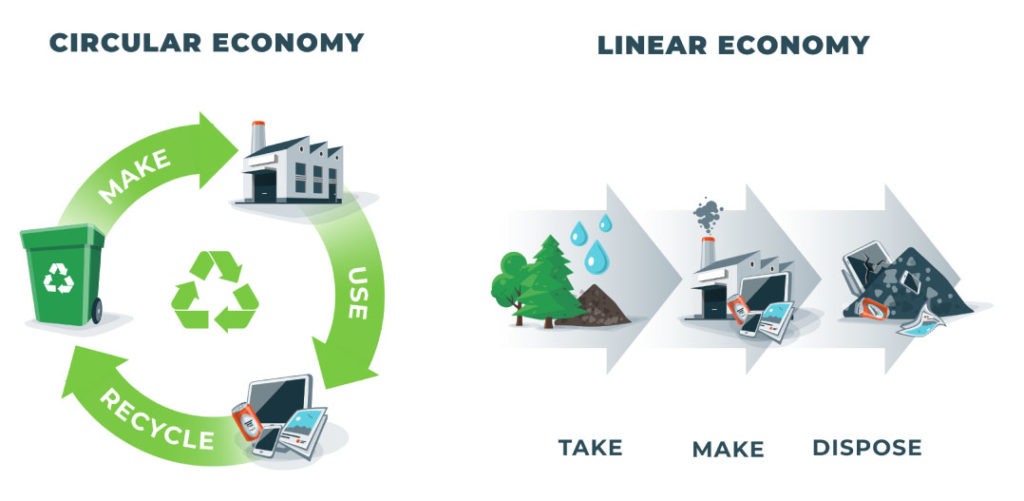

For several decades, the prevalent economic philosophy across numerous industries both on the national and international level supported a linear economic model – in which resources were drawn from the natural world, manufactured into products, and disposed of when their intended usage was completed. The assumptions of a linear economy were that natural resources were plentiful, the consequences of discarding materials after use were minimal, and that disposal of used products was more convenient and cost-effective than recycling.

However, as awareness has increased about the effects of climate change and the importance of sustainability, and those first two precepts of the linear model were challenged, businesses also came to discover that the third assumption of a linear economy was also flawed – in fact, it can be far more cost-effective to continue to re-use materials for as long as they can be made useful, and then return them to the ecosystem in a sustainable way. This contrasting model can be described as a circular economy.

Wooden pallets are the predominant form of moving material throughout the United States supply chain.

The precise definition of Circular Economy, as outlined by the Hellen McArthur Foundation, is “the process of eliminating waste and pollution, keeping products and materials in use, and regenerating natural systems.” This can mean extending the useful life of a product through repair, redistribution of products after their initial owner is finished with them, reclaiming the materials that make up a product for re-use, keeping damaged products and materials from becoming pollution in landfills and oceans, minimizing the production of greenhouse gases (GHG) that contribute to climate change at all stages of the product’s life cycle, and finding a sustainable treatment for the waste materials that remain at the end of the product’s useful life.

The recycled wood pallet industry is an excellent example of CE (circular economy) in action. To begin with, the primary component of most pallets is wood, a highly renewable material when sustainably cultivated and harvested. The hardwood and softwood trees that are harvested to make pallets are also one of our most essential natural tools for carbon sequestration, a critical component of the effort to mitigate GHG pollution. In this respect, wood pallets already have an edge over pallets made of alternate materials such as plastic or metal, the production of which tends to leave a much larger carbon footprint.

Once a fresh wooden pallet enters circulation, it can be expected to suffer some wear and tear through normal use and transportation, but wood pallet recycling can substantially extend its useful life. Support blocks or replacement boards – themselves reclaimed from other damaged pallets – can be added to repair any structural damage the pallet had suffered. After a number of uses, the worn and damaged pallet is dismantled and its components inspected for soundness; the sturdy boards of this and other pallets are combined with new hardware, labor, and energy to create more new pallets, just as functional as those constructed from fresh timber, but more affordable and less wasteful. Any lumber from recycled pallets that has become too damaged can be turned into energy or returned to the ecosystem via composting. As such, pallet recycling upholds the three principles of Circular Economy:

- Reduction or elimination of waste

- Keeping products circulating within the economy and extending their useful life; and

- Helping to sustain and regenerate natural ecosystems

As it turns out, the principles of Circular Economy are not only sustainable and beneficial from an ecological perspective, but through a business lens as well. Green marketing has become an increasing draw for customers and clients, but there are far more direct economic benefits to be gained from using recycled wooden pallets, beyond appealing to potential customers’ sense of ecological responsibility. Quite simply, recycled pallets are less expensive, because recycled pallet manufacturers are focused on getting the most utility out of the least amount of materials.

In an environmental product declaration (EPD) released by the Pallet Foundation and the National Wooden Pallet and Container Association, it was estimated that a new pallet would make between 10 and 66 trips with only one set of repairs. If, instead of being discarded as waste, that pallet continued to be repaired and recycled for as long as its lumber remained viable, it would have the potential for several times that many trips without adding new wood to the system.

Pallet recycling companies often partner with warehouses and distributors to collect their used pallets to be recycled, which helps enable these pallet manufacturers to supply quality wood pallets at competitive prices. This provides the pallet recycling company with additional materials, and also saves the warehouse the trouble and expense of disposing of their used pallets, while keeping usable wood out of landfills. The wood pallet recycling industry is an excellent example of how Circular Economy can help businesses both remain ecologically responsible and improve profits.

About Greenway Products & Services

Greenway Products & Services, LLC is the largest pallet re-manufacturer and recyclers in NY, NJ, PA, MD, and DE. We also accept scrap wood from our customers that we turn into valuable resources. Greenway is a highly-rated, full-service pallet management company. Contact us for a quote today at sales@greenwaypsllc.com. Visit our website, greenwaypsllc.com or call us at 732-442-0200. We can deliver trailers to you on a moment’s notice throughout the NY-NJ-PA-MD-DE Mid-Atlantic area.

Leave A Comment